Exploring Rubber Products Volume – 1

Exploring Rubber Products: Versatility, Innovation, and Impact

Rubber products are an integral part of modern life, serving a multitude of functions across various industries. From the humble tire on a vehicle to advanced medical devices, rubber’s versatility and durability make it indispensable. This essay explores the significance of rubber products, the various types of rubber polymers and their physical properties, their diverse applications, the innovations driving their development, and the environmental considerations associated with their use.

1. The Significance of Rubber Products

Rubber, both natural and synthetic, offers a range of properties that make it ideal for numerous applications. Natural rubber, derived from the latex of rubber trees (Hevea brasiliensis), is prized for its elasticity, resilience, and flexibility. Synthetic rubbers, such as neoprene and silicone, are engineered to offer enhanced properties tailored for specific uses. The significance of rubber products lies in their ability to withstand harsh conditions, absorb shocks, and provide sealing solutions that are vital for safety and functionality in various applications.

2. Types of Rubber Polymers and Their Physical Properties

Rubber polymers can be broadly categorized into natural and synthetic types, each with distinct physical properties suited for specific applications:

- Natural Rubber (NR): Derived from the latex of the rubber tree, natural rubber is known for its excellent elasticity, resilience, and flexibility. It has high tensile strength and abrasion resistance, making it ideal for applications that require durability and stretchability. Common uses include automotive tires, gaskets, and footwear.

- Styrene-Butadiene Rubber (SBR): A synthetic rubber made from styrene and butadiene, SBR is widely used in tires and various industrial products. It offers good abrasion resistance, aging stability, and weather resistance. SBR is less elastic than natural rubber but provides a balance of performance and cost-effectiveness.

- Neoprene (Polychloroprene): This synthetic rubber is known for its resistance to oils, chemicals, and weathering. It retains flexibility over a wide temperature range and is used in applications such as wetsuits, gaskets, and automotive parts.

- Butyl Rubber (IIR): Made from isobutylene and a small amount of isoprene, butyl rubber is impermeable to gases and has excellent aging and weather resistance. It is commonly used in inner tubes for tires, pharmaceuticals, and as a sealing material.

- Silicone Rubber (VMQ): Silicone rubber is known for its high temperature stability, flexibility, and resistance to moisture and chemicals. It maintains its properties over a wide temperature range and is used in applications such as medical devices, kitchenware, and seals.

- Ethylene Propylene Diene Monomer (EPDM): EPDM is known for its excellent resistance to heat, ozone, and weathering. It is widely used in roofing membranes, seals, and automotive parts.

- Thermoplastic Elastomers (TPEs): TPEs combine the properties of rubber with the processing advantages of plastics. They are used in a variety of applications, including automotive parts, consumer goods, and medical devices, due to their flexibility, durability, and ease of processing.

3. Diverse Applications

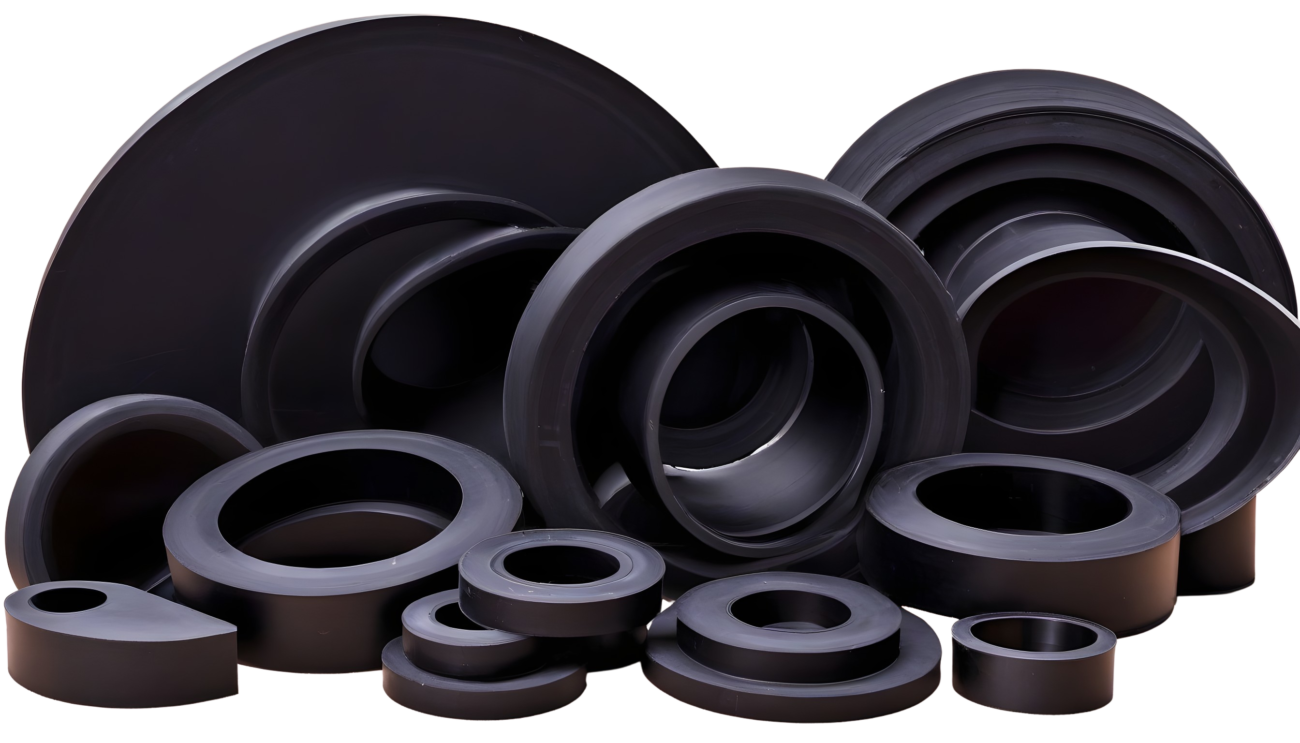

The applications of rubber products are vast and varied. In the automotive industry, rubber is primarily used in tires, seals, and gaskets. Tires made from rubber provide traction, stability, and safety on the road, while seals and gaskets prevent leaks and ensure efficient operation of engines and other components. In the construction sector, rubber is utilized in the form of roofing materials, flooring solutions, and vibration isolation systems, contributing to building durability and comfort.

Medical applications of rubber products are also noteworthy. Rubber gloves, catheters, and other medical devices rely on rubber’s biocompatibility and flexibility. These products play a critical role in maintaining hygiene and ensuring the proper function of medical procedures. Additionally, rubber is used in various consumer goods, from footwear to household items, where its durability and comfort enhance the quality of daily life.

4. Innovations Driving Development

The development of rubber products has been greatly influenced by advances in materials science and engineering. Innovations in synthetic rubber production have led to the creation of specialty rubbers that exhibit unique properties such as high heat resistance, chemical resistance, and improved elasticity. For example, the development of thermoplastic elastomers (TPEs) has enabled the production of rubber-like materials that can be molded and remolded, offering flexibility in design and manufacturing.

Furthermore, advancements in compounding techniques have allowed for the customization of rubber products to meet specific requirements. The incorporation of fillers, reinforcements, and additives enhances the performance of rubber in diverse environments. Innovations in recycling and sustainability are also transforming the rubber industry, with efforts focused on developing eco-friendly materials and processes that reduce the environmental impact of rubber products.

5. Environmental Considerations

Despite their many benefits, rubber products pose environmental challenges. Natural rubber production involves deforestation and habitat destruction, while synthetic rubbers contribute to pollution through the use of petrochemicals. The disposal of rubber products, particularly tires, poses another environmental concern due to their resistance to degradation.

Addressing these issues requires a multifaceted approach. The development of sustainable practices in rubber cultivation, such as responsible sourcing and reforestation efforts, can mitigate environmental impacts. Advances in recycling technologies are also crucial, with ongoing research focused on improving the efficiency of rubber recycling processes and finding innovative ways to reuse rubber materials.

6. Conclusion

Rubber products are a testament to human ingenuity and the quest for practical solutions to everyday challenges. Their diverse applications span across automotive, construction, medical, and consumer sectors, underscoring their importance in modern society. The variety of rubber polymers, each with its distinct physical properties, enhances the adaptability and functionality of rubber products. Innovations in material science continue to enhance rubber’s performance and versatility, while ongoing efforts to address environmental concerns reflect a growing commitment to sustainability. As we explore the potential of rubber products, it is essential to balance technological advancements with responsible environmental practices, ensuring that the benefits of rubber continue to enhance our lives while minimizing its ecological footprint.